-

Workshop highly specialised in hard stones

HANDCRAFTING TECHNIQUES AND NEW GENERATION TECHNOLOGIES -

Technologies applied to detailed processing

SMALL AND LARGE PROCESSED OBJECTS -

Highly qualified labour to create every piece

INNOVATIVE HANDCRAFTING TECHNIQUES TO MEET EVERY REQUEST

OUR HARD STONE PROCESSING EXPERTISE SERVES EVERY PRODUCTION TYPE

Didoni’s handcrafting skills are at the service of projects custom-designed by architects and designers. We create unique items, samples and small series. We also produce large quantities. We engrave customised decorations in various finishes, such as the family coat-of-arms or initials.

Stone cutting

We have dedicated cutters for small and large blocks of hard stone. Stone cutting is the first processing phase. We also provide third-party cutting services.

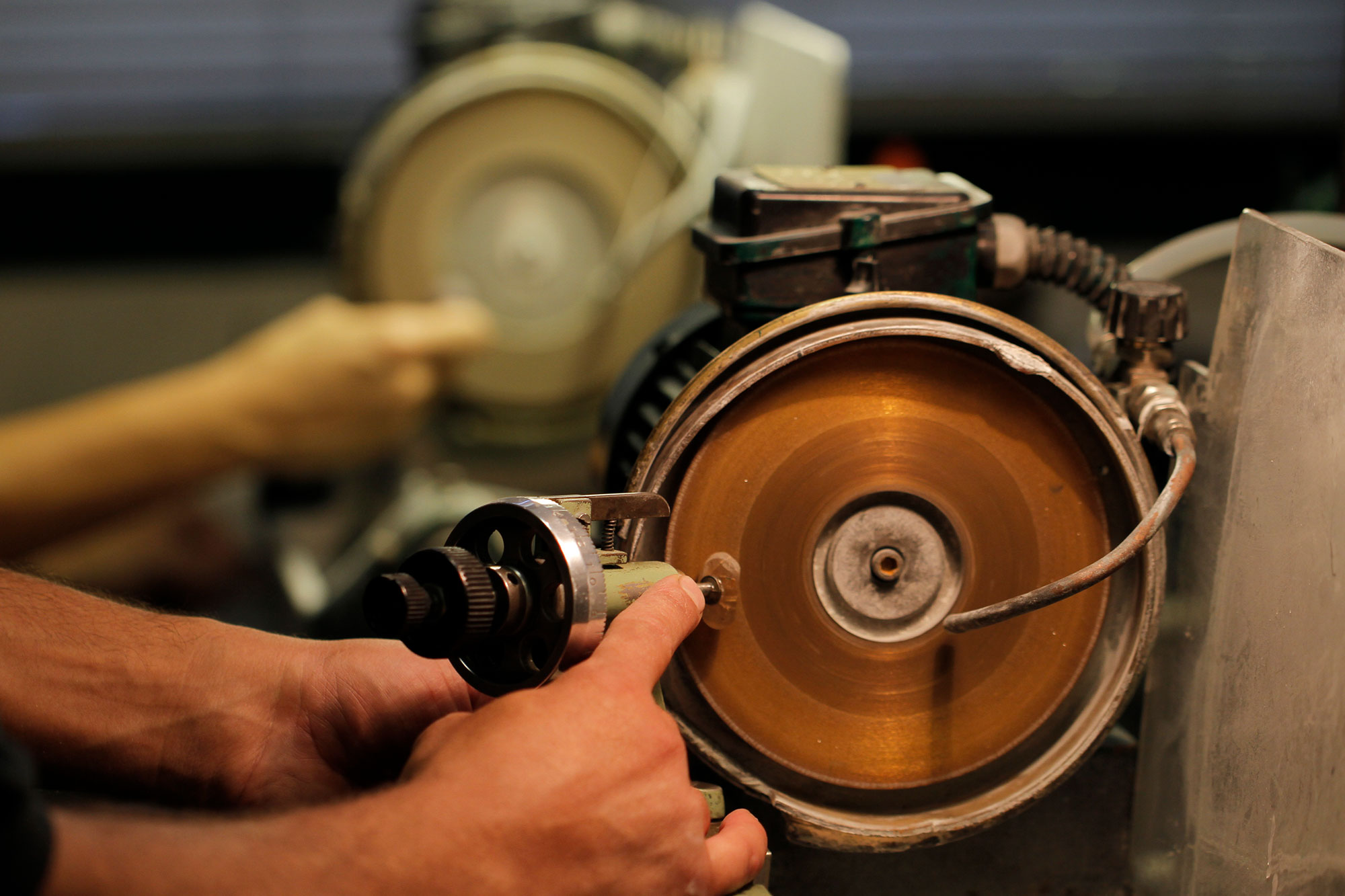

Cabbing

This processing method allows to create stones devoid of facets for jewellery and furnishing details.

Inlaying

The inlaying technique is applied to the decoration of objects, furniture and floors. Starting from the client’s design, we create simple or complex inlaid work in high quality precious and semiprecious hard stones of various sizes, with the utmost care for details.

Faceting

We are equipped to facet gems and semiprecious stones for customised jewels, designer collections, and design and furnishing elements.

Drilling holes

We use diamond-tip drills to create through holes or half holes with miscellaneous diameter. This service is offered to clients who request custom-made jewellery.

Tumble finish

Raw stones are placed in a machine called tumbler in which the sharp edges of stones are rounded and smoothed. The tumble finish is the ideal choice for the surface finish of a large number of pieces, both small and large.

Polishing

Polishing is performed on individual jewels after careful evaluation. We are also equipped to smooth and polish large surfaces to achieve the desired finish.

Shaped finish

We produce turned items with low tolerance, based on client specifications. This technique yields handles, vases and cups. Individual or mass-produced items.